Made in Italy

Care and passion for each yarn

Production

Italian quality in all its shapes

Our range includes men’s and women’s double and single cylinder socks in cotton, lisle cotton, unshrinkable wool, cashmere and silk in several different gauges; all items are stretched in order to have a single size. In addition to classic models, Calzificio Bonadei is specialized in the production of fancy patterned socks thanks to the internal graphics office and to collaborations with external stylists.

Flexibility in production and in meeting customer needs makes us an excellent partner for those who wish to customize their line with “Private labels”.

Design office

The design office is the link between customer ideas and their realization: it collects customer instructions and shares samples of more than 3000 items created during all the years in business. It then develops stylistic proposals with 2D and 3D rendering techniques specific for the sock business.

At this step we check the feasibility and develop patterns and designs for the machinery following the selected yarns cards.

Raw materials

We only choose safe and reliable suppliers of raw materials, who respect standards of quality and responsibility that characterize Italian excellence, and who ensure rapid delivery.

Thanks to these consolidated partnerships and to a warehouse where we store the most frequently used yarns, effectively replicating the yarn colour cards of our main suppliers, we reduce as much as possible the preparation lead time of production.

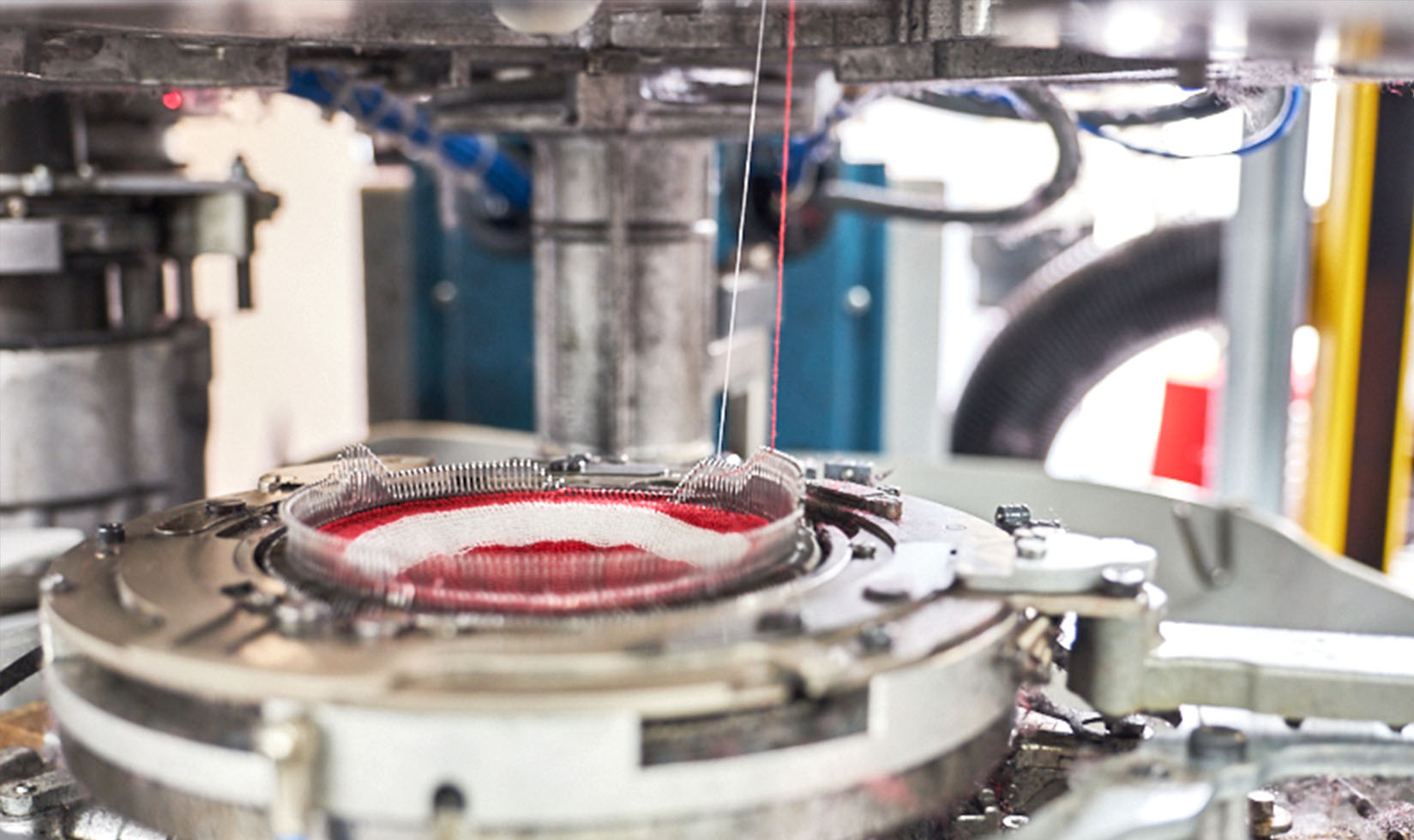

Machinery

The Machines Room turns into products all the projects designed by the Design Office: following all the different instructions, the prototypes are created and, once confirmation is received from the customer, the Head of the Production Area coordinates workers and mechanics to start the work agreeing the expected delivery date.

Quality Check 1

The first quality check is performed while production is still in progress to ensure that subsequent processing is carried out only on items that are consistent with our standards of excellence.

Upon leaving the machines room, each single sock is examined for any defects, so a 100% QC is carried out at this initial stage: unsuitable items are discarded and all the recoverable raw material is regenerated for new uses.

Link

Hand linking consists in joining exactly the ranks of the toe with those of the foot, making the seam as thin as possible, almost imperceptible: this technique is typical of higher quality socks and creates less hassle from rubbing with shoes on.

This operation is made using special linking machines, which remain faithful to our artisan tradition.

Ironing

Once knitting is complete, socks are washed to cancel any residues and to ennoble fibres, then ironed and aligned with care on special boards, ready for pairing.

Pairing

Under the watchful and expert eyes of our employees, special machines automatically pair up the socks according to the length, with a tolerance of a few millimeters.

Quality Check 2

To ensure the achievement of our standards of excellence, a second quality check is done, to cut any threads and discard the defective socks.

Heat Transfer

Based on the agreements with the customers, socks are transferred in a delectable or indelible way and the tissue paper is inserted, before the final packaging processes.

Packaging

In this phase, we apply labels by sewing the riders, we fold the pair of socks and we add hangers, swing tags and stickers.

Shipping

The items are boxed according to the customer’s needs in standard sizes boxes.

For specific packaging needs, the internal Graphic Department provides support for the design, while our suppliers provide us with materials to make these ad hoc packages.